Mohala oa Tlhahiso o Kopantsoeng oa RDS13 CNC oa Saw le Drill

| Ntho | paramethara | Tlhaloso |

| Mohlala oa motheo oa terene | Mofuta oa thepa | 50Kg/m,60 Kg/m,75 Kg/m thatafalo 340~400HB |

| Terene ea motheo ea tšepe ea alloy, tšepe ea alloy, boima ba 38 HRC~45 HRC | ||

| Boholo ba terene | Bolelele ba thepa e tala | 2000~1250mm |

| Litlhoko tsa ts'ebetso | Thepabolelele | 1300~800mm |

| Thepamamello ea bolelele | ± 1mm | |

| Ho otloloha ha sefahleho sa pheletso | <0.5mm | |

| Bophara ba ho cheka | φ31~φ60mm | |

| Bophara ba lesobamamello | 0~0.5mm | |

| Bophahamo ba lesoba | 60~100mm | |

| Litekanyetso tse ka sehloohong tsa botekgeniki tsa mochini | Mokhoa oa ho saga | Sakha e chitja (lebelo le phahameng) |

| Matla a enjene ea spindle | 37kW | |

| Bophara ba lehare la sakha | Φ660mm | |

| Lebelo le phahameng la ho falla la X axis | 25m/motsotso | |

| Lebelo le phahameng ka ho fetisisa la ho falla ha axis ea Z | 6m/motsotso | |

| Mofuta oa ho cheka spindle | BT50 | |

| Ho chekaLebelo la lehoakhoa | 3000r/motsotso | |

| Ho chekaMatla a enjene ea servo ea spindle | 37kW | |

| Lebelo le phahameng ka ho fetisisa la ho falla ha X, Y, Z axis | 12m/motsotso | |

| Mofuta oa lesokoana la ho tjhesa | NT40 | |

| Sehokelo sa ho tjhesa ka chamfering RPM Max. | 1000 | |

| Matla a enjene ea chamfering spindle | 2.2 kW | |

| Lebelo la motsamao oa Y2 axis le Z2 axis | 10m/motsotso | |

| Chuck ea makenete ea motlakase e sa feleng | 250×200×140mm(e 'ngoe200×200×140mm) | |

| Ho monya mosebetsi | ≥250N/cm² | |

| Sistimi ea ho tlosa li-chip | 2sete | |

| Mofuta oa sekepe sa chip | Ketane e bataletseng | |

| Lebelo la ho tlosa ditshipi | 2m/motsotso | |

| Sistimi ea CNC | Siemens828D | |

| Palo ea litsamaiso tsa CNC | Sete tse 2 | |

| Palo ea lilepe tsa CNC | 6+1 axis,Mokhahlelo oa 2+1 | |

| Bolelele ba tafole ea mosebetsi | 700mm | |

| Bolelele ba tafole ea mosebetsi | hoo e ka bang 37.8m×8m×3.4m |

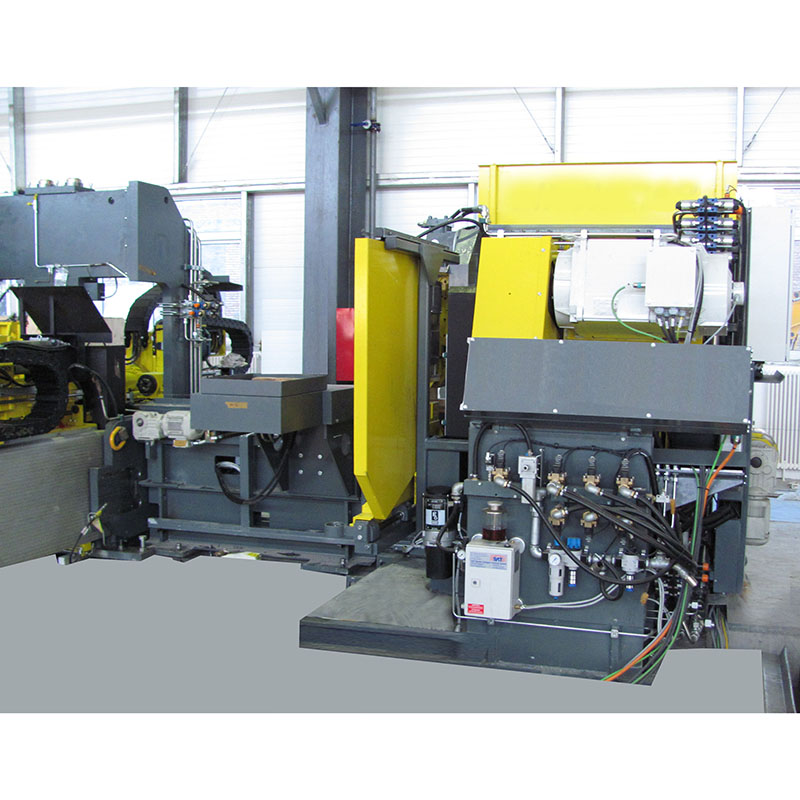

1. Ho na le sesebelisoa sa ho tlosa lehare la sakha holim'a sesebelisoa sa ho seha, se ikarabellang bakeng sa ho tlosa lerole la sakha ho tsoa lehareng la sakha. Sesebelisoa sa ho pholisa le ho tlotsa se tlotsa le ho pholisa sebaka sa ho seha, e leng se ntlafatsang bophelo ba ts'ebeletso ea lehare la sakha. lireile tsa tataiso, 'me kholomo e tsamaeang e kentsoe betheng ea mochini.

2. Sistimi ea ho ngola khoutu

Sistimi ea ho ngola khoutu e kentsoe ka lehlakoreng le ka ntle la ram ea hlooho ea motlakase, 'me e na le khomphutha e amohelang ho hlophisa le ho laola sistimi ea ho ngola khoutu.

3. Yuniti ea ho cheka

Sebopeho sa kholomo sea amoheloa, 'me kholomo e amohela sebopeho se kopantsoeng ka poleiti ea tšepe. Kamora kalafo ea ho annealing le ea botsofali ba maiketsetso, botsitso ba ho nepahala ha ts'ebetso boa netefatsoa.

4. Hlooho ea ho cheka

Sekoahelo sa ho tjheka ke sebopeho sa mofuta wa ram se nang le ho tiea ho matla. Lebanta la nako le na le matla a ho thapolla a hodimo, bophelo bo bolelele, lerata le tlase le ho thothomela ho tlase ha le sebetsa ka lebelo le phahameng. Sekoahelo se nepahetseng se phodiswa kahare mme se na le sekoti, mme se na le mokgwa wa ho phunya manala a mane a 45°. Karolo e ka morao ya sekoahelo se nepahetseng e na le silindara ya ho phunya ka hydraulic bakeng sa ho nkela sesebediswa sebaka habonolo.

5. Benche ea mosebetsi

Benche ea mosebetsi e amohela sebopeho sa ho tjheseletsa poleiti ea tšepe, kalafo ea pele e etsoa pele ho tjheseletsa, 'me ka mor'a ho tjheseletsa, phomolo ea khatello ea maikutlo le kalafo ea botsofali ba mocheso lia etsoa ho netefatsa ho nepahala le botsitso.

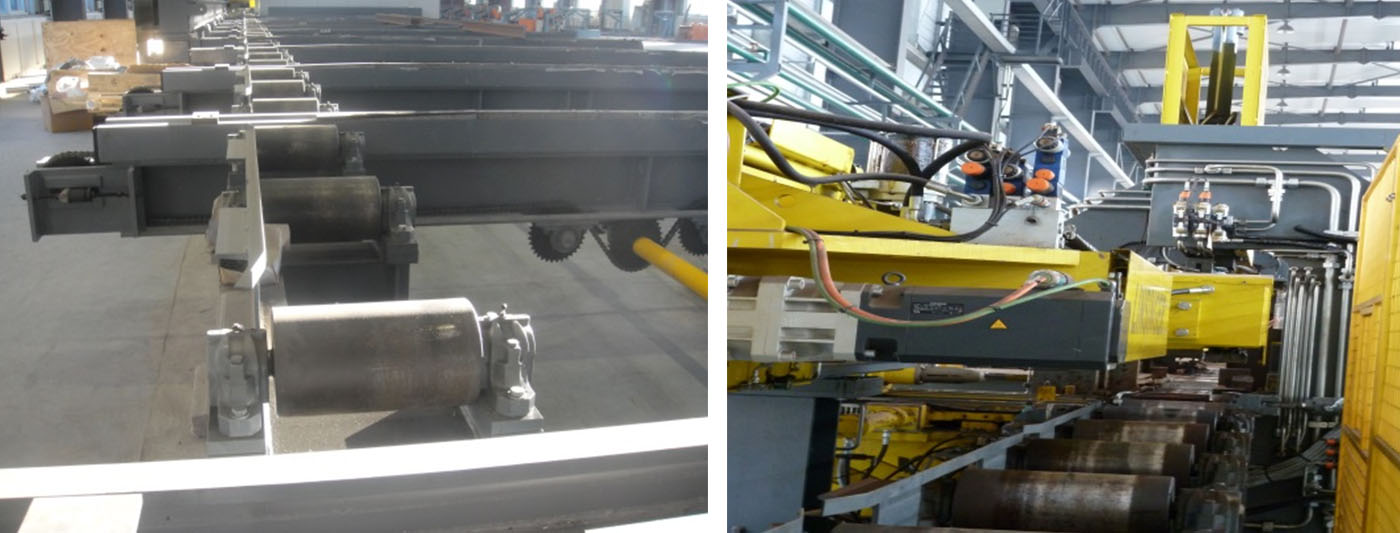

6. Sistimi ea ho tlosa li-chip

Sepalangoang sa chip se iketsang ke mofuta oa ketane e bataletseng, ka kakaretso ea lisete tse peli. Sete e 'ngoe e sebelisetsoa yuniti ea ho seha 'me e beoa tlas'a lehlakore la lehare la sakha. Sete e 'ngoe e sebelisetsoa yuniti ea ho cheka, e behiloeng pakeng tsa bethe le benche ea mosebetsi. Lifaelo tsa tšepe li oela holim'a sepalangoang sa chip ka tataiso ea chip bencheng ea mosebetsi, 'me lifaelo tsa tšepe li isoa lebokoseng la ho faela tšepe hloohong ka sepalangoang sa chip.

7. Sistimi ea ho tlotsa

Ho na le disete tse pedi tsa ditsamaiso tsa ho tlotsa tse iketsang tse bohareng, e nngwe bakeng sa yuniti ya ho seha le e nngwe bakeng sa yuniti ya ho tjheka. Sistimi ya ho tlotsa e iketsang e etsa ho tlotsa ho sa kgaotseng hodima para ya tataiso e otlolohileng, para ya dikurufu tsa bolo, le para ya rack le pinion ho netefatsa ho nepahala ha tsona le bophelo ba tshebeletso.

8. Sistimi ea motlakase

Sistimi ea motlakase e sebelisa sistimi ea taolo ea lipalo ea Siemens 828D, lisete tse peli kaofela, sete e le 'ngoe e sebelisoa ho laola yuniti ea ho saga, raka ea ho fepa e rapameng, tafole ea rolara ea ho fepa le tafole ea rolara e bohareng. Sete e 'ngoe e sebelisoa ho laola yuniti ea ho cheka, benche ea mosebetsi ea 1, raka ea ho laolla e rapameng le benche ea mosebetsi.

| CHE. | Ntho | Letšoao | Tšimoloho |

| 1 | Para ea tataiso e otlolohileng | HIWIN | Taiwan, Chaena |

| 2 | Sistimi ea CNC 828D | Siemens | Jeremane |

| 3 | Senjene ea ervo | Siemens | Jeremane |

| 4 | Sistimi ea ho ngola khoutu | Printer ea LDMinkjet | Shanghai, Chaena |

| 5 | Pompo ea oli ea haeteroliki | Justmark | Taiwan, Chaena |

| 6 | Ketane ea ho hula | CPS | Korea Boroa |

| 7 | Likere, liraka | APEX | Taiwan, Chaena |

| 8 | Sefokotsi sa ho nepahala | APEX | Taiwan, Chaena |

| 9 | Sekotwana sa ho tjheseletsa ka nepo | KENTURN | Taiwan, Chaena |

| 10 | Likarolo tse ka sehloohong tsa motlakase | Schneider | Fora |

Ela Hloko: Se kaholimo ke mofani oa rona oa thepa ea tloaelehileng. Se ka nkeloa sebaka ke likarolo tsa boleng bo tšoanang tsa mofuta o mong oa thepa haeba mofani ea kaholimo a sa khone ho fana ka likarolo haeba ho ka ba le ntho efe kapa efe e ikhethang.

Profaele e Khutšoanyane ea Khamphani  Tlhahisoleseling ea Feme

Tlhahisoleseling ea Feme  Bokgoni ba Tlhahiso ya Selemo le Selemo

Bokgoni ba Tlhahiso ya Selemo le Selemo  Bokhoni ba Khoebo

Bokhoni ba Khoebo