Mochini oa ho Cheka oa CNC oa RDL25A Bakeng sa Literene

| Tlhaloso ea seporo se sebetsitsoeng | Mofuta oa terene | 43Kg/m,50Kg/m,60Kg/m,75Kg/m,UIC54,UIC60 |

| ATmohlala oa terene | 50AT,60 AT,UIC60D40 | |

| Terene ea mapheo a karolo e khethehileng | 60TY | |

| Mefuta ea boholo ba terene | Bophara bo ka tlase | 114-152mm |

| Bolelele ba terene | 128-192mm | |

| Webbotenya | 14.5-44mm | |

| Bolelele ba seporo (kamora ho seha) | 6-25m | |

| Mofuta oa thepa ea terene | U71Mn σb≥90Kg/mm² HB250PD3 σb≥98Kg/mm² HB290-310 | |

| Ho chekahlooho | Bophara | φ20~φ33 |

| Bolelele ba sebaka | 3D~4D | |

| Litlhoko tsa ts'ebetso | Bophahamo ba lesoba | 35~100mm |

| Holibophara linomorotereneng ka 'ngoe | 1~4 mefuta | |

| E lumelletsoemamellosebaka sa masoba a haufi | ± 0.3mm | |

| E lumelletsoemamellopakeng tsa sefahleho sa pheletso ea terene le sebaka se haufi sa lesoba | ± 0.5mm | |

| E lumelletsoemamellosebaka se hole ka ho fetisisa sa seporo | ± 0.5mm | |

| E lumelletsoemamelloeabophara ba lesobaboholo | 0~+0.3mm | |

| Ho se tsitse ha lebota la masoba | Ra12.5 | |

| E lumelletsoemamelloea bophahamo ba setsi sa lesoba (ho tloha tlase ho seporo) | ± 0.3mm | |

| Kholomo e tsamaeang (ho kenyeletsoa le ho phunyaho inglebokose la motlakase) | Bongata | Sete e le 1 |

| Lesoba la theipi le nang le lesoba | BT50 | |

| Lebelo la spindle (taolo ea lebelo le se nang mehato) | 10~3200r/motsotso | |

| Matla a enjene ea Servo ea spindle | 37kW | |

| Leeto la ho thellisa le otlolohileng (mothapo oa Y) | 800mm | |

| Matla a enjene ea servo ea slide e otlolohileng (Y-axis) | 3.1kw | |

| Sefuba sa ho cheka se otlolohileng (setsi sa Z) | 350mm | |

| Matla a motlakase oa servo motor (Z axis) a ho cheka ka ho otloloha | 3.1kw | |

| Kolomo e otlolohileng ea ho tsamaea (X axis) | 25m | |

| Motsamao o otlolohileng wa kholomo (X axis) matla a servo motor | 3.1kw | |

| Lebelo le phahameng ka ho fetisisa la ho falla la X-axis | 10m/motsotso | |

| Lebelo le phahameng ka ho fetisisa la ho falla la Y, Z axis | 8m/motsotso | |

| Sesebelisoa sa ho suna makenete sa motlakase sa kamehla | Bongata | Sete e le 1 |

| Boholo ba motsu (L × w × h) | 250×200×120mm | |

| Ho monya ho sebetsa | ≥200N/cm² | |

| Silindara e sutumelletsang lehlakoreng | Bophara ba silindara × setoroko | Φ50×70mm |

| Sekoahelo sa lehlakore sa silindara e le 'ngoe | 700Kg | |

| Tafole e phahamisang | Bongata | Sete e le 1 |

| Lebelo la ho fetisa | ≤15m/motsotso | |

| Silindara e thusang ea ho tšoara fatše | Bongata | Sete e le 1 |

| Matla a ho hatella | ≥1500Kg/sete | |

| Ho tlosoa ha chip | Mofuta oa sekepe sa chip | Ketane e bataletseng |

| Lebelo la ho tlosa ditshipi | 2m/motsotso | |

| Matla a enjene ea ho tlosa chip | 2.2kW | |

| Sistimi ea haeteroliki | Bongata | Lisete tse 2 |

| Khatello ea pompo ea haeteroliki / phallo / matla | 6-6.5Mpa/25L/min/4kW sete e le 1 | |

| Khatello ea pompo ea haeteroliki / phallo / matla | 5.5-6Mpa/66L/min/7.5kW sete e le 1 | |

| Sistimi ea motlakase | Sistimi ea taolo ea linomoro | Siemens 828D |

| Palo ea lilepe tsa CNC | 5+1 | |

| Mohloli oa moea | Khatello ea phepelo ea moea e hatelletsoeng | 0.6Mpa |

| Litekanyo ka kakaretso | (L× W× H) | Hoo e ka bang 57×8.7×3.8m |

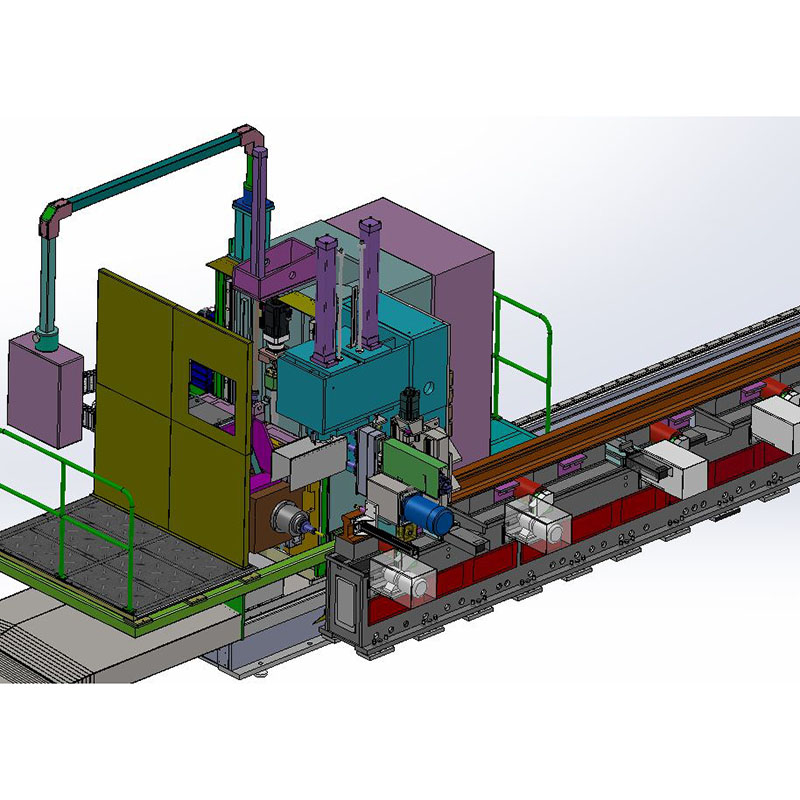

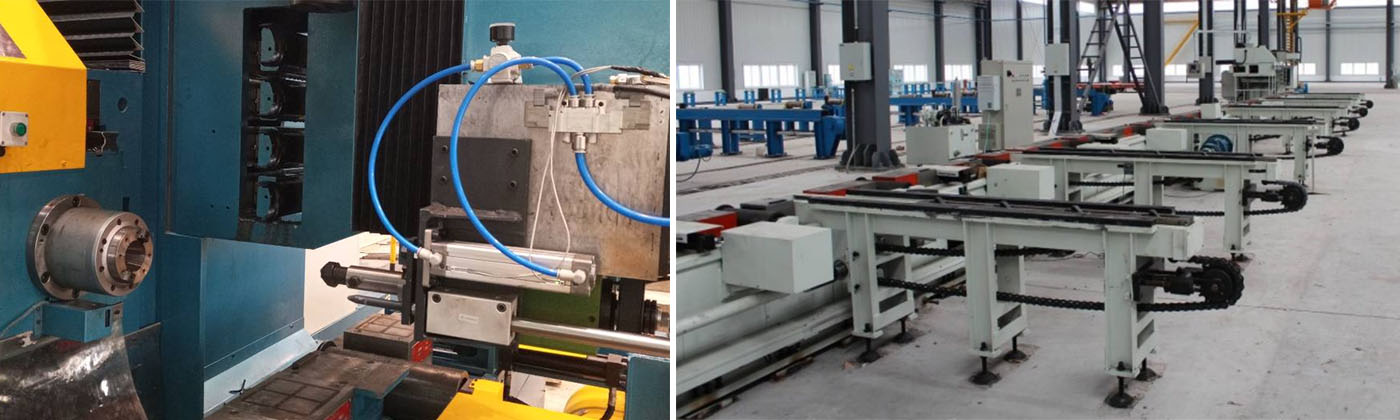

1. Bethe ea mochini e arotsoe tafoleng ea mosebetsi, 'me para ea seporo sa tataiso ea bethe e hlophisitsoe ka ho otloloha ho eketsa bophelo ba tšebeletso ea para ea seporo sa tataiso; Sebopeho sa poleiti ea tšepe e welded sea amoheloa, 'me ho nepahala le botsitso li netefatsoa ka ho annealing, ho imolla khatello ea maikutlo le kalafo ea botsofali ea maiketsetso.

2. Sekotwana se matla sa motlakase se kentswe tafoleng ya mosebetsi ya sesebediswa sa mochini ho tiisa thepa. Ela hloko tatellano ho tloha bohareng ho ya mahlakoreng ka bobedi ha sesupa-matla sa motlakase se kwetswe, mme o ele hloko ho kwala le ho se kenelle metsi.

3. Kholomo e tsamayang e amohela sebopeho sa ho tjheseletsa poleiti ya tshepe, se kentsweng ho tlosa kgatello ya maikutlo le kalafo ya botsofadi ba maiketsetso ho netefatsa botsitso bo nepahetseng.

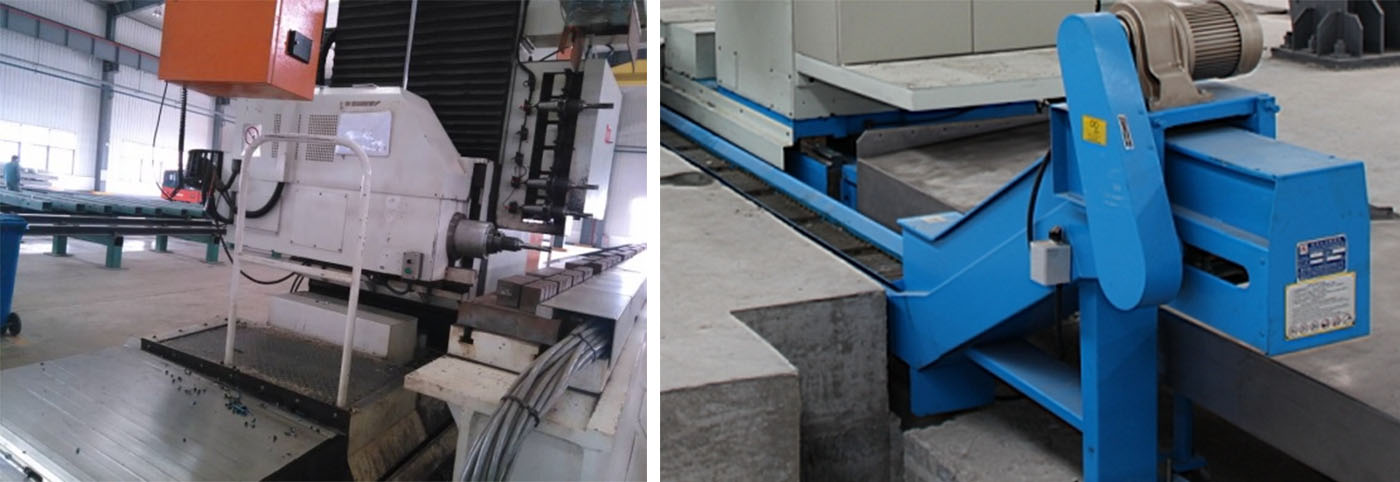

4. Sesebelisoa sa ho tlosa chip ka boiketsetso sa poleiti ea ketane ke mofuta oa ketane e bataletseng, 'me se kentsoe bohareng ba tafole ea mosebetsi ea bethe.

5. Mochini o na le liteishene tse peli tsa hydraulic, e 'ngoe e kentsoe kholomong e tsamaeang, e sebelisoang haholo-holo bakeng sa ho leka-lekanya silindara, silindara e hatellang le silindara ea thipa; E 'ngoe e kentsoe motheong, e sebelisoang haholo-holo bakeng sa ho phahamisa silindara le ho hula silindara ea tafole e tsamaisang rolara e phahamisang.

6. Ho na le lilepe tse tharo tsa CNC ka har'a mochini, tseo e 'ngoe le e 'ngoe ea tsona e tataisoang ke para ea tataiso e otlolohileng e otlolohileng.

7. Sesebelisoa sa ho tjheka se sebedisa drile ya carbide e kgonang ho tjheka, mme spindle e phodiswa ke moholi wa moya.

8. Sistimi ea Siemens 828D CNC e sebelisoa tsamaisong ea CNC, e ka behang leihlo ts'ebetso ea ho cheka ka nako ea sebele.

| NO. | Lebitso | Letšoao | Naha |

| 1 | Para ea tataiso ea bolo | HIWIN/PMI | Taiwan (Chaena) |

| 2 | CNCsistimi | Siemens 828D | Jeremane |

| 3 | Senjene ea ervo | Siemens | Jeremane |

| 4 | Valve ea haeteroliki | ATOS | Italy |

| 5 | Pompo ea oli | Justmark | Taiwan (Chaena) |

| 6 | Ketane ea ho hula | IGUS/CPS | Jeremane / Korea |

| 7 | Enjene ea servo ea spindle | Siemens | Jeremane |

| 8 | Sefokotsi | ATLANTA | Jeremane |

| 9 | Sekotwana sa ho tjheseletsa ka nepo | Kenturn | Taiwan (Chaena) |

Ela Hloko: Se kaholimo ke mofani oa rona oa thepa ea tloaelehileng. Se ka nkeloa sebaka ke likarolo tsa boleng bo tšoanang tsa mofuta o mong oa thepa haeba mofani ea kaholimo a sa khone ho fana ka likarolo haeba ho ka ba le ntho efe kapa efe e ikhethang.

Profaele e Khutšoanyane ea Khamphani  Tlhahisoleseling ea Feme

Tlhahisoleseling ea Feme  Bokgoni ba Tlhahiso ya Selemo le Selemo

Bokgoni ba Tlhahiso ya Selemo le Selemo  Bokhoni ba Khoebo

Bokhoni ba Khoebo