Mochini oa ho Cheka oa PLM4020 Gantry o ka tsamaisoang oa CNC Plate

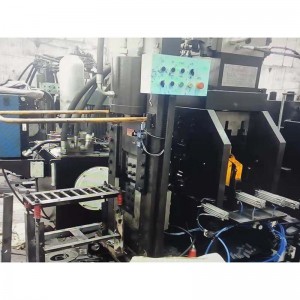

(1) 'Mele oa foreimi ea mochini le mahlakore a tšekaletseng li entsoe ka sebopeho se entsoeng ka ho kopanngoa, ka mor'a kalafo e lekaneng ea mocheso ea ho tsofala, ka ho nepahala ho hoholo. Tafole ea mosebetsi, tafole e thellang e tšelang le pheleu kaofela li entsoe ka tšepe e entsoeng ka tšepe.

(2) Sistimi ea ho khanna ea servo e habeli ea mahlakore a mabeli ho X axis e netefatsa motsamao o nepahetseng oa gantry o bapileng, le boholo bo botle ba Y axis le X axis.

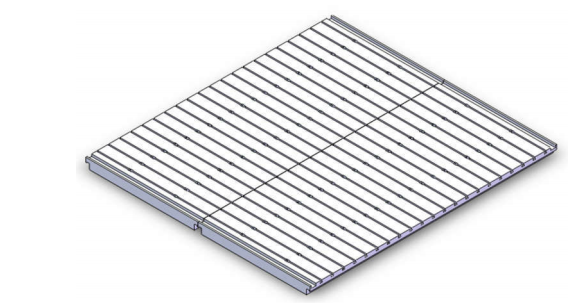

(3) Tafole ea mosebetsi e sebelisa sebopeho se tsitsitseng, tšepe ea boleng bo holimo le mokhoa o tsoetseng pele oa ho lahla, ka bokhoni bo boholo ba ho jara.

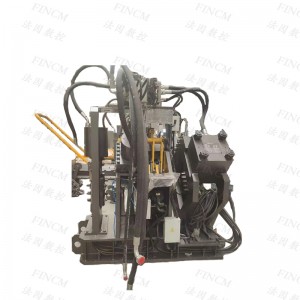

(4) Setulo se thata haholo sa ho bea, bere e sebelisa mokhoa oa ho kenya ka morao, bere e khethehileng e nang le screw e nepahetseng haholo.

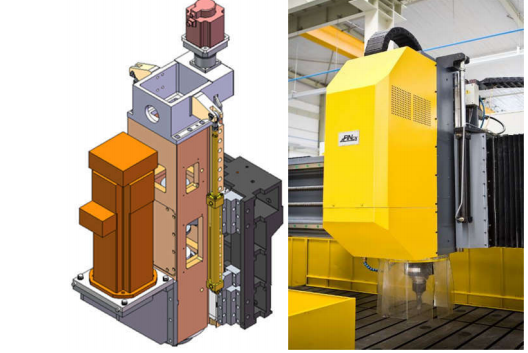

(5) Motsamao o otlolohileng (Z-axis) oa hlooho ea motlakase o tataisoa ke lipara tse tataisang tse otlolohileng tse hlophisitsoeng mahlakoreng ka bobeli a pheleu, tse nang le ho nepahala ho hoholo, khanyetso e phahameng ea ho thothomela le coefficient e tlase ea khohlano.

(6) Lebokose la matla a ho tjheka ke la mofuta wa spindle e tiileng e nepahetseng, e amohelang spindle ya ho phodisa ya kahare ya Taiwan BT50. Lesoba la spindle cone le na le sesebediswa sa ho hlwekisa, mme le ka sebedisa drill ya ho phodisa ya kahare ya carbide e samentetsweng, ka ho nepahala ho hoholo. Spindle e kgannwa ke motor ya servo spindle e matla haholo ka lebanta le tshwanang, karolelano ya phokotso ke 2.0, lebelo la spindle ke 30~3000r/min, mme lebelo le pharaletseng.

(7) Mochini o sebelisa li-chip remover tse peli tse bataletseng ka mahlakoreng ka bobeli a tafole ea mosebetsi. Li-chip tsa tšepe le sehatsetsi li bokelloa ka har'a sehatsetsi sa chip. Li-chip tsa tšepe li isoa ho sehatsetsi sa chip, e leng se loketseng haholo ho tlosoa ha chip. Sehatsetsi se sebelisoa hape.

(8) Mochini o fana ka mefuta e 'meli ea mekhoa ea ho pholisa - ho pholisa ka hare le ho pholisa ka ntle. Pompo ea metsi e nang le khatello e phahameng e sebelisoa ho fana ka sesebelisoa se pholileng se hlokahalang bakeng sa ho pholisa ka hare, ka khatello e phahameng le phallo e kholo.

(9) Mochini o na le sistimi ea ho tlotsa e iketsang, e pompang oli e tlotsang ka har'a boloko bo thellang ba para e tataisang e otlolohileng, screw pair ea bolo le screw bearing ea karolo ka 'ngoe khafetsa ho etsa setlolo se lekaneng le se tšepahalang ka ho fetisisa.

(10) Lireile tsa tataiso tsa X-axis mahlakoreng ka bobeli a mochini li na le likoahelo tse sireletsang tsa tšepe e sa ruseng, 'me lireile tsa tataiso tsa Y-axis li kentsoe ka likoahelo tse sireletsang tse tenyetsehang.

(11) Sesebelisoa sa mochini se boetse se na le sesebelisoa sa ho fumana mahlakore a motlakase ho nolofatsa ho beha likarolo tse chitja tsa mosebetsi.

(12) Sesebelisoa sa mochini se entsoe le ho kenngwa ka disebediswa tse felletseng tsa polokeho. Moqhaka wa gantry o na le sethala sa ho tsamaya, lera la ho sireletsa, le lere la ho hloa lehlakoreng la kholomo ho netefatsa polokeho ya basebetsi ba tshebetso le ba tlhokomelo. Sekoahelo se bonolo sa PVC se bonaletsang se kentswe ho potoloha mosi o moholo.

(13) Sistimi ea CNC e na le Siemens 808D kapa Fagor 8055, e nang le mesebetsi e matla. Sebopeho sa ts'ebetso se na le mesebetsi ea puisano ea motho le mochini, puseletso ea liphoso le alamo e iketsang. Sistimi e na le lebili la letsoho la elektroniki, le bonolo ho le sebelisa. E na le khomphutha e nkehang habobebe, lenaneo la othomathiki la CAD-CAM le ka etsoa ka mor'a hore software e kaholimo ea khomphutha e kenngoe.

| Ntho | Lebitso | Boleng |

|---|---|---|

| Boholo ba Poleiti | L x W | 4000×2000 mm |

| Boholo ba Poleiti | Bophara | Φ2000mm |

| Boholo ba Poleiti | Botenya bo boholo | 200 mm |

| Tafole ea Mosebetsi | Bophara ba Sebaka sa T | 28 mm (e tloaelehileng) |

| Tafole ea Mosebetsi | Tekanyo ea tafole ea mosebetsi | 4500x2000mm (LxW) |

| Tafole ea Mosebetsi | Boima ba ho kenya | 3 ton/㎡ |

| Sehokelo sa ho tjheka | Bophara bo boholo ba ho cheka | Φ60 mm |

| Sehokelo sa ho tjheka | Bophara bo boholo ba ho thapa | M30 |

| Sehokelo sa ho tjheka | Bolelele ba Thupa ea spindle ea ho cheka khahlanong le bophara ba lesoba | ≤10 |

| Sehokelo sa ho tjheka | RPM | 30~3000 r/min |

| Sehokelo sa ho tjheka | Mofuta oa theipi ea spindle | BT50 |

| Sehokelo sa ho tjheka | Matla a enjene ea spindle | 22kW |

| Sehokelo sa ho tjheka | Torque e phahameng ka ho fetisisa (n≤750r/min) | 280Nm |

| Sehokelo sa ho tjheka | Sebaka se tlohang holim'a leqhubu le ka tlase ho ea tafoleng ea mosebetsi | 280 ~ 780 mm (e ka fetoloa ho latela botenya ba thepa) |

| Motsamao oa Longitudinal oa Gantry (X Axis) | Maeto a Maholo | 4000 mm |

| Motsamao oa Longitudinal oa Gantry (X Axis) | Lebelo la motsamao ho latela X axis | 0~10m/motsotso |

| Motsamao oa Longitudinal oa Gantry (X Axis) | Matla a enjene ea Servo ea X axis | 2 × 2.5kW |

| Motsamao oa Sekotwana sa ho Fetoha (Y Axis) | Maeto a Maholo | 2000mm |

| Motsamao oa Sekotwana sa ho Fetoha (Y Axis) | Lebelo la motsamao ho latela Y axis | 0~10m/motsotso |

| Motsamao oa Sekotwana sa ho Fetoha (Y Axis) | Matla a enjene ea Servo ea Y axis | 1.5kW |

| Motsamao oa ho Fepa ka Sekotwana (Z Axis) | Maeto a Maholo | 500 mm |

| Motsamao oa ho Fepa ka Sekotwana (Z Axis) | Lebelo la ho fepa la axis ea Z | 0~5m/motsotso |

| Motsamao oa ho Fepa ka Sekotwana (Z Axis) | Matla a enjene ea Servo ea axis ea Z | 2kW |

| Ho nepahala ha sebaka | Sekhahla sa X, Sekhahla sa Y | 0.08/0.05mm/leeto lohle |

| Ho nepahala ha boemo bo ka phetoa-phetoang | Sekhahla sa X, Sekhahla sa Y | 0.04/0.025mm/leeto lohle |

| Sistimi ea haeteroliki | Khatello ea pompo ea haeteroliki/Sekhahla sa phallo | 15MPa /25L/motsotso |

| Sistimi ea haeteroliki | Matla a enjene ea pompo ea hydraulic | 3.0kW |

| Sistimi ea pneumatic | Khatello ea moea e hatelletsoeng | 0.5 MPa |

| Sistimi ea ho tlosa likhechana le ho pholisa | Mofuta oa ho tlosa lithōle | Ketane ea poleiti |

| Sistimi ea ho tlosa likhechana le ho pholisa | Linomoro tsa ho tlosa lithōle. | 2 |

| Sistimi ea ho tlosa likhechana le ho pholisa | Lebelo la ho tlosa lithōle | 1m/motsotso |

| Sistimi ea ho tlosa likhechana le ho pholisa | Matla a Motlakase | 2 × 0.75kW |

| Sistimi ea ho tlosa likhechana le ho pholisa | Tsela e pholileng | Pholisetsa ea ka hare + Pholisetsa ea kantle |

| Sistimi ea ho tlosa likhechana le ho pholisa | Khatello e Phahameng | 2MPa |

| Sistimi ea ho tlosa likhechana le ho pholisa | Sekhahla sa phallo se phahameng ka ho fetisisa | 50L/motsotso |

| Sistimi ea elektroniki | Sistimi ea taolo ea CNC | Siemens 808D |

| Sistimi ea elektroniki | Linomoro tsa Axis tsa CNC | 4 |

| Sistimi ea elektroniki | Matla ohle | Hoo e ka bang 35kW |

| Tekanyo e Akaretsang | L×W×H | Hoo e ka bang 10×7×3m |

| Tjhe. | Lebitso | Letšoao | Naha |

|---|---|---|---|

| 1 | Seporo sa tataiso sa Roller Linear | Hiwin | Chaena Taiwan |

| 2 | Sistimi ea taolo ea CNC | Siemens/ Fagor | Jeremane/Spain |

| 3 | Ho fepa servo motor le mokhanni oa servo | Siemens/Panasonic | Jeremane/Japane |

| 4 | Sekotwana se nepahetseng | Spintech/Kenturn | Chaena Taiwan |

| 5 | Valve ea haeteroliki | Yuken/Justmark | Japane/Chaena Taiwan |

| 6 | Pompo ea oli | Justmark | Chaena Taiwan |

| 7 | Sistimi ea ho tlotsa ka boiketsetso | Herg/BIJUR | Japane/Amerika |

| 8 | Konopo, Sesupo, likarolo tsa elektroniki tsa motlakase o tlase | ABB/Schneider | Jeremane/Fora |

| Tjhe. | Lebitso | Boholo | Bongata. |

|---|---|---|---|

| 1 | Sesebelisoa sa ho fumana bohale ba optical | Sekotwana se le seng | |

| 2 | Sesepa sa hexagon se ka hare | Sete e le 1 | |

| 3 | Sehokelo sa lisebelisoa le stud ea ho hula | Φ40-BT50 | Sekotwana se le seng |

| 4 | Sehokelo sa lisebelisoa le stud ea ho hula | Φ20-BT50 | Sekotwana se le seng |

| 5 | Lipente tse ling | – | Li-keg tse 2 |

1. Phepelo ea motlakase: mekhahlelo e 3 ea 5 380+10%V 50+1HZ

2. Khatello ea moea e hatelletsoeng: 0.5MPa

3.Mocheso: 0-40℃

4.Mongobo: ≤75%