Mochini oa ho cheka oa selefouno oa PLM Series CNC Gantry

| Item | Name | paramethara | |||

| PLM3030-2 | PLM4040-2 | PLM5050A-2 | PLM6060-2 | ||

| Ho sebetsa ka bongata haholothepaboholo | Bolelele x bophara | 3000*3000 mm | 4000×4000 mm | 5000×5000 mm | 5000×5000 mm |

| Botenya ba poleiti bo boholo bo sebetsitsoeng | 250 mm, E ka atolosoa ho fihlela ho 380mm | ||||

| Mosebetsitafole | Boholo ba benche ea mosebetsi | 3500×3000 mm | 4500×4000 mm | 5500×4000 mm | 5500×4000 mm |

| Bophara ba groove ea T | 28 mm | ||||

| Le jereng moqhaka | 3tli-ons/㎡ | ||||

| Ho chekaSekotwana sa ho phunya | Boholoho chekabophara ba lesoba | φ60 mm | |||

| Karolelano e phahameng ka ho fetisisaBolelele ba Sesebelisoa khahlanong le Bophara ba Lesoba | ≤10()Moqhakakhabideho phunya) | ||||

| Sekotwana sa ho phunyaRPM | 30-3000 r/motsotso | ||||

| Sekotwana sa ho tjheseletsa | BT50 | ||||

| Matla a enjene ea spindle | 2×22kW | ||||

| Torque e kholo ea spindlen≤750r/motsotso | 280Nm | ||||

| Sebaka ho tloha sefahlehong se ka tlase saspindleho ea tafoleng ea mosebetsi | 280—780 mm ()Fetola ho latelathepabotenya) | ||||

| Motsamao oa bolelele ba gantry (x-axis) | Setoroko se phahameng ka ho fetisisa | 3000 mm | 4000 mm | 5000 mm | |

| Lebelo la ho sisinyeha ha X-axis | 0—8m/motsotso | ||||

| Matla a enjene ea servo ea X-axis | 2×2.7kW | ||||

| Pho nepahala ha ho beha | Mokhahlelo oa X、Mokhahlelo oa Y | 0.06mm/ kaofelastroke | 0.08mm/ kaofelastroke | 0.10mm/ kaofelastroke | |

| Pheta ho nepahala ha boemo | Mokhahlelo oa X、Mokhahlelo oa Y | 0.035mm/ kaofelastroke | 0.04mm/ kaofelastroke | 0.05mm/ kaofelastroke | |

| Sistimi ea haeteroliki | Khatello/phallo ea pompo ea haeteroliki | 15MPa /25L/motsotso | |||

| Matla a enjene ea pompo ea hydraulic | 3.0 kW | ||||

| Sistimi ea pneumatic | Khatello ea phepelo ea moea | 0.5 Mpa | |||

| Ho tlosa le ho pholisa chip | Mofuta oa sekepe sa chip | Ketane e bataletseng | |||

| Palo ea sesebelisoa sa ho tsamaisa chip | 2 | ||||

| Lebelo la ho tlosa ditshipi | 1m/motsotso | ||||

| Matla a enjene ea chip conveyor | 2 × 0.75kW | ||||

| Mokhoa oa ho pholisa | Pholisetsa ea ka hare + pholisetsa ea kantle | ||||

| Khatello e phahameng ka ho fetisisa | 2MPa | ||||

| Phallo e phahameng ka ho fetisisa | 2×50L/motsotso | ||||

| Sistimi ea motlakase | CNC | Siemens 828D | |||

| CNCmotsoakoNomoro | 6 | ||||

| Matla a felletseng a enjene | Hoo e ka bang 75kW | ||||

| Litekanyo tse akaretsang tsa sesebelisoa sa mochini | Bolelele × Bophara × Bophahamo | Mabapi le 8m×8m×3m | Mabapi le9m×9m×3m | Mabapi le10m×10m×3m | Mabapi le10m×10m×3m |

| Boima bohle ba sesebelisoa sa mochini | Hoo e ka bang 32t | Mabapi le40t | Mabapi le48t | ||

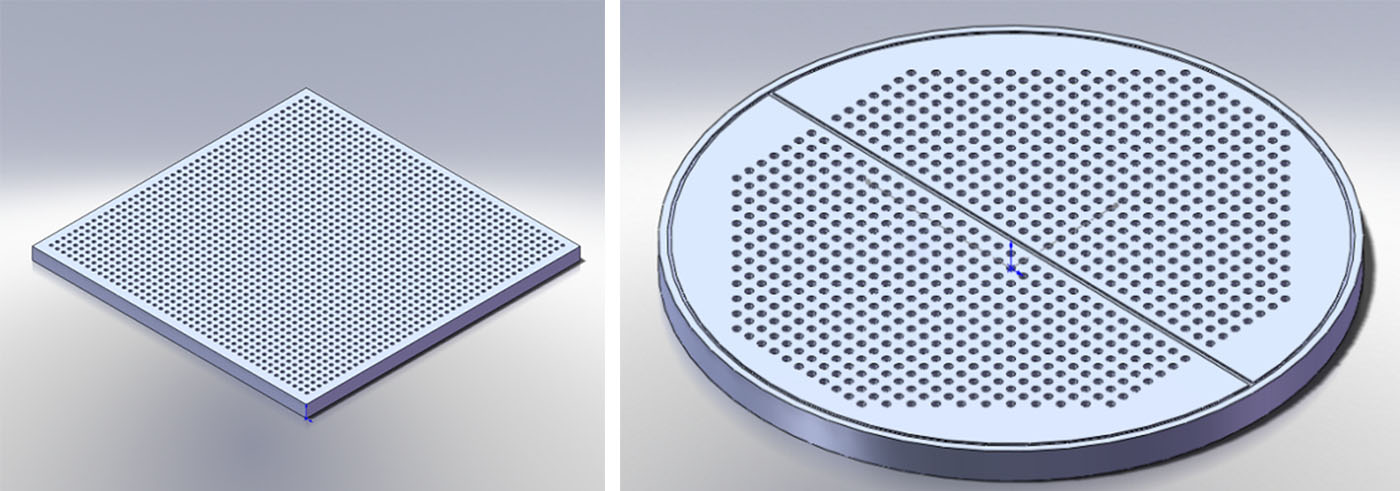

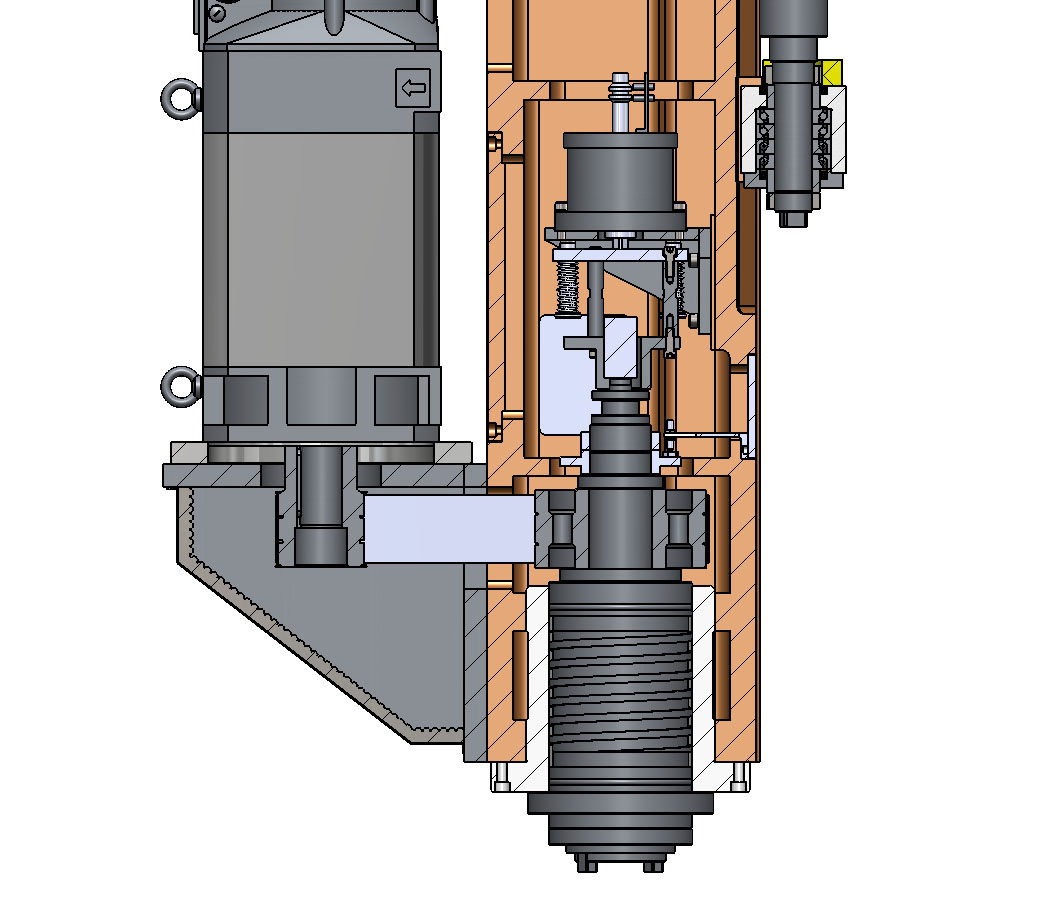

1. Mochini ona o entsoe haholo-holo ka bethe le kholomo, boriti le tafole e thellang e otlolohileng, lebokose la matla a ho cheka la mofuta oa ram o otlolohileng, tafole ea mosebetsi, sesebelisoa sa ho tsamaisa chip, sistimi ea hydraulic, sistimi ea pneumatic, sistimi ea ho pholisa, sistimi ea ho tlotsa e bohareng, sistimi ea motlakase, jj.

2. Motheo oa ho bea o tiileng haholo, bea e sebelisa bea e khethehileng ea screw e nepahetseng haholo. Bokaholimo ba motheo ba ho hokela bo bolelele bo eketsehileng bo netefatsa ho tiea ha axial. Bearing e tiisitsoe esale pele ke nati ea senotlolo, 'me screw ea lead e hatelloa esale pele. Palo ea ho otlolla e khethoa ho latela phetoho ea mocheso le ho lelefatsa screw ea lead ho netefatsa hore ho nepahala ha sebaka sa screw ea lead ha ho fetohe kamora hore mocheso o nyolohe.

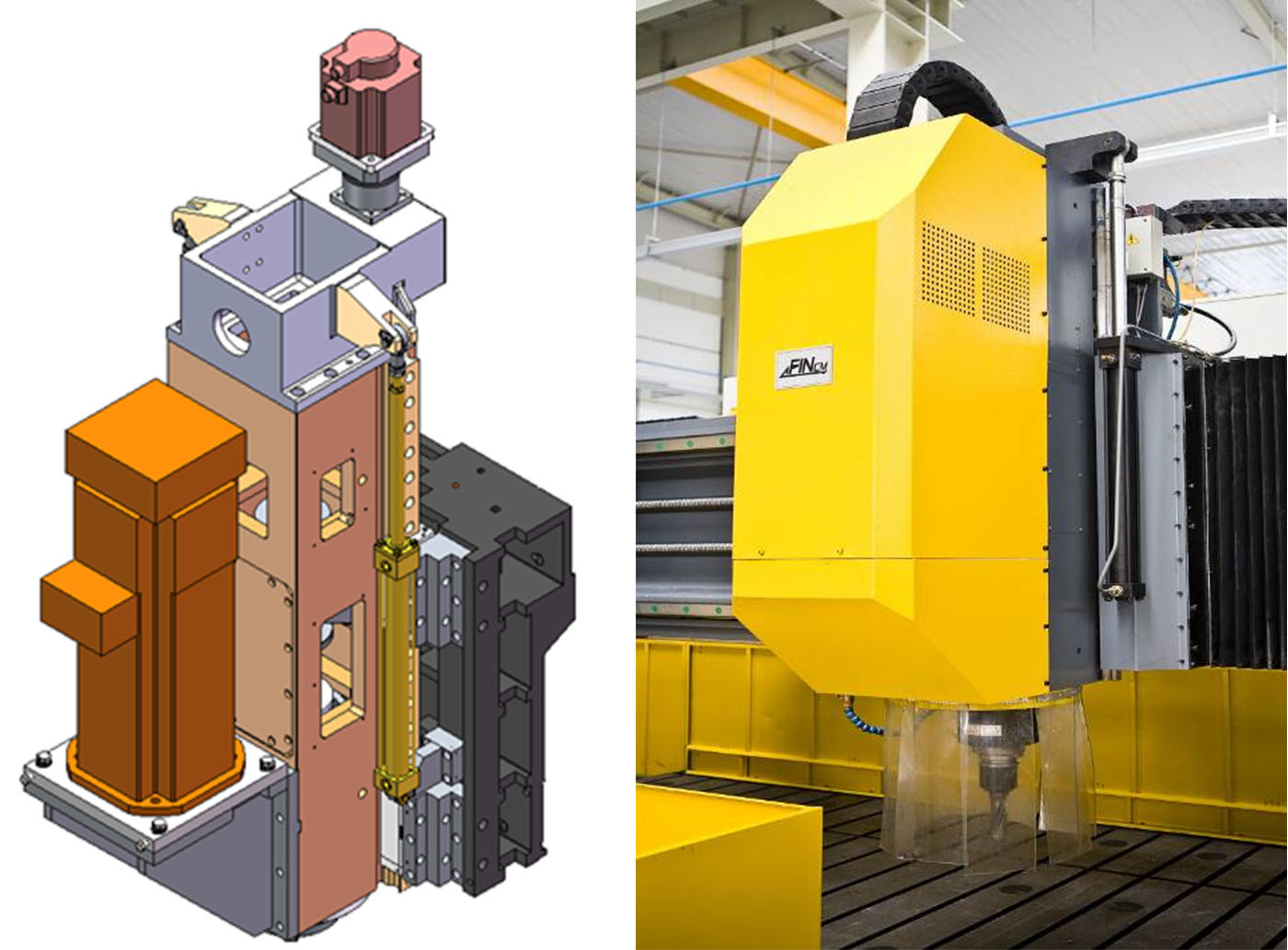

Hlooho ea matla a ho cheka le ho sila

3. Motsamao o otlolohileng (Z-axis) oa hlooho ea motlakase o tataisoa ke litataiso tse peli tse otlolohileng tse hlophisitsoeng holim'a pheleu, tse nang le ho nepahala ho hotle ha tataiso, khanyetso e phahameng ea ho thothomela le coefficient e tlase ea khohlano. Koloi ea skrufu ea bolo e tsamaisoa ke enjene ea servo ka sesebelisoa se fokotsang lipolanete hantle, se nang le matla a mangata a ho fepa.

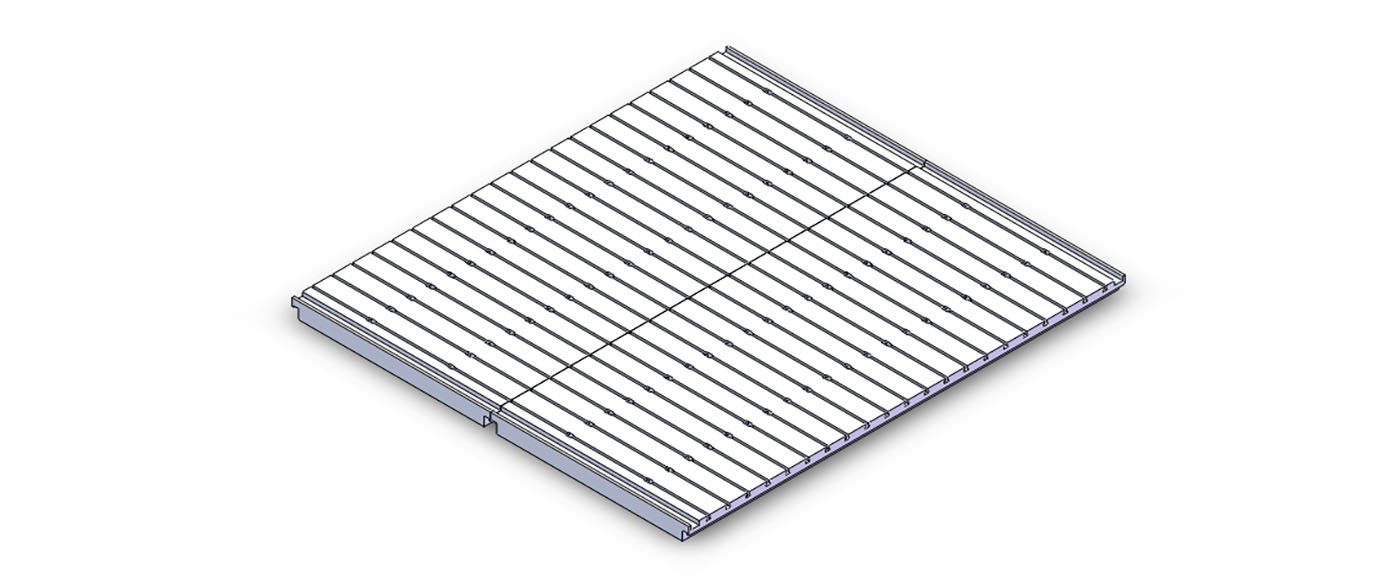

4. Mochini ona o amohela li-conveyor tse peli tsa ketane e bataletseng mahlakoreng ka bobeli a tafole ea mosebetsi. Li-chip tsa tšepe le sehatsetsi li bokelloa ka har'a sehatsetsi sa chip, 'me li-chip tsa tšepe li isoa ho sehatsetsi sa chip, e leng se loketseng haholo ho tlosoa ha chip; sehatsetsi se sebelisoa hape.

5. Mochini ona o fana ka mekhoa e 'meli ea ho pholisa—ho pholisa ka hare le ho pholisa ka ntle, e fanang ka setlolo le ho pholisa sesebedisweng lethepanakong ea ho seha li-chip, e leng se tiisang horeho phunyaboleng ba ho pholile. Lebokose la ho pholisa le na le dikarolo tsa ho lemoha boemo ba metsi le alamo, mme kgatello e tloaelehileng ya ho pholisa ke 2MPa.

Sekotwana sa ho tjheseletsa ka nepo

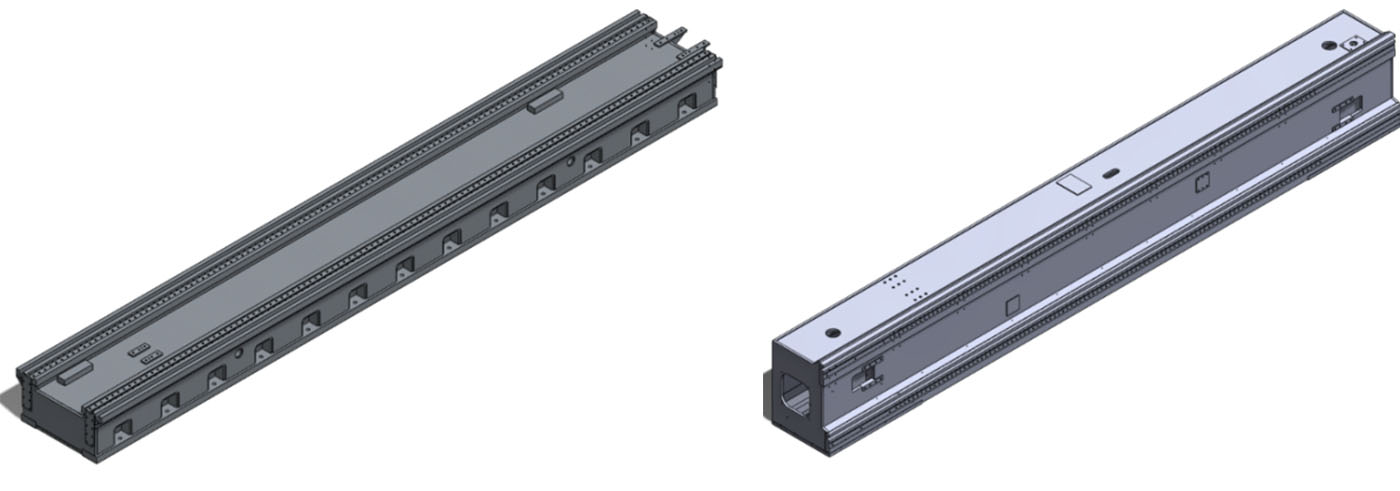

6. Lireile tsa tataiso tsa X-axis mahlakoreng ka bobeli a mochini li na le likoahelo tse sireletsang tsa tšepe e sa ruseng, 'me lireile tsa tataiso tsa Y-axis li na le likoahelo tse sireletsang tse tenyetsehang mahlakoreng ka bobeli.

Sepalangoang sa chip

Sesebelisoa sa ho pholisa

Sesebelisoa sa ho tlotsa ka boiketsetso

7. Mochini ona o boetse o na le sesebelisoa sa ho fumana mahlakore a motlakase ho nolofatsa boemo ba poleiti e chitja.

Sistimi ea Siemens CNC

| CHE. | Lebitso | Letšoao | Naha |

| 1 | Terene e tataisang e otlolohileng | HIWIN kapa PMI | Taiwan, Chaena |

| 2 | Sistimi ea Taolo ea CNC | Siemens | Jeremane |

| 3 | Enjene ea Servo le mokhanni | Siemens | Jeremane |

| 4 | Sekotwana sa ho tjheseletsa ka nepo | KENTURN kapa SPINTECH | Taiwan, Chaena |

| 5 | Valve ea haeteroliki | YUKEN KAPA Justmark | Japane |

| 6 | Pompo ea oli | Justmark | Taiwan, Chaena |

| 7 | Sistimi ea ho tlotsa ka boiketsetso | BIJUR KAPA HERG | USA kapa Japane |

| 8 | Likonopo, mabone a ponts'o le likarolo tse ling tsa motlakase tse ka sehloohong | SCHBEIDER/ABB | Fora/Jeremane |

Ela Hloko: Se kaholimo ke mofani oa rona oa thepa ea tloaelehileng. Se ka nkeloa sebaka ke likarolo tsa boleng bo tšoanang tsa mofuta o mong oa thepa haeba mofani ea kaholimo a sa khone ho fana ka likarolo haeba ho ka ba le ntho efe kapa efe e ikhethang.

Profaele e Khutšoanyane ea Khamphani  Tlhahisoleseling ea Feme

Tlhahisoleseling ea Feme  Bokgoni ba Tlhahiso ya Selemo le Selemo

Bokgoni ba Tlhahiso ya Selemo le Selemo  Bokhoni ba Khoebo

Bokhoni ba Khoebo