Mochini oa ho Cheka oa China Angle Steel CNC o entsoeng ka fektheri o rekisoang haholo

Meaho ea rona e hlomelitsoeng hantle le taolo e ntle e ikhethang mekhahlelong eohle ea tlhahiso e re nolofalletsa ho netefatsa khotsofalo e felletseng ea bareki bakeng sa Mochini oa ho Cheka oa China Angle Steel CNC o rekisoang fekthering, Re amohela bareki ba mose ho maoatle ka tieo ho buisana bakeng sa tšebelisano-'moho ea nako e telele le nts'etsopele ea bobeli. Re lumela ka tieo hore re ka etsa betere le ho feta.

Libaka tsa rona tse hlomelitsoeng hantle le taolo e ntle haholo mekhahlelong eohle ea tlhahiso li re nolofalletsa ho netefatsa khotsofalo e felletseng ea bareki bakeng saMohala oa Angle oa China CNC, Mochini oa CNCHape re na le likamano tse ntle tsa tšebelisano-'moho le bahlahisi ba bangata ba molemo e le hore re ka fana ka hoo e ka bang likarolo tsohle tsa likoloi le tšebeletso ea kamora thekiso ka maemo a boleng bo holimo, boemo bo tlase ba theko le tšebeletso e mofuthu ho fihlela litlhoko tsa bareki ba tsoang masimong a fapaneng le libakeng tse fapaneng.

Morero oa Mochini

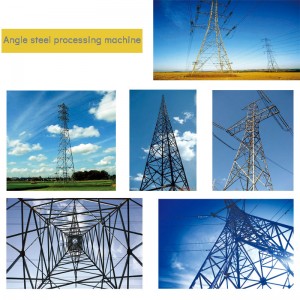

Morero ona oa mochini o sebelisoa haholo-holo bakeng sa li-workpiece tsa poleiti ea ho cheka meahong ea tšepe e kang kaho, coaxial, tora ea tšepe, jj., 'me e ka boela ea sebelisoa bakeng sa lipoleiti tsa tube tsa ho cheka, li-baffle le li-flange tse chitja liboilers, indastering ea petrochemical; botenya bo boholo ba ts'ebetso ke 100mm, Liboto tse tšesaane tsa khale le tsona li ka kenngoa ka mekhahlelo e mengata bakeng sa ho cheka, bokhoni bo phahameng le ho nepahala ho phahameng.

Morero ona oa mochini o ka sebelisoa bakeng sa tlhahiso e tsoelang pele ea boima, hammoho le tlhahiso e nyane ea mefuta e mengata, 'me o ka boloka mananeo a mangata a mesebetsi. Mesebetsi e hlahisitsoeng e ka sebelisoa bakeng sa ho sebetsana le mesebetsi ea mofuta o tšoanang nakong e tlang.

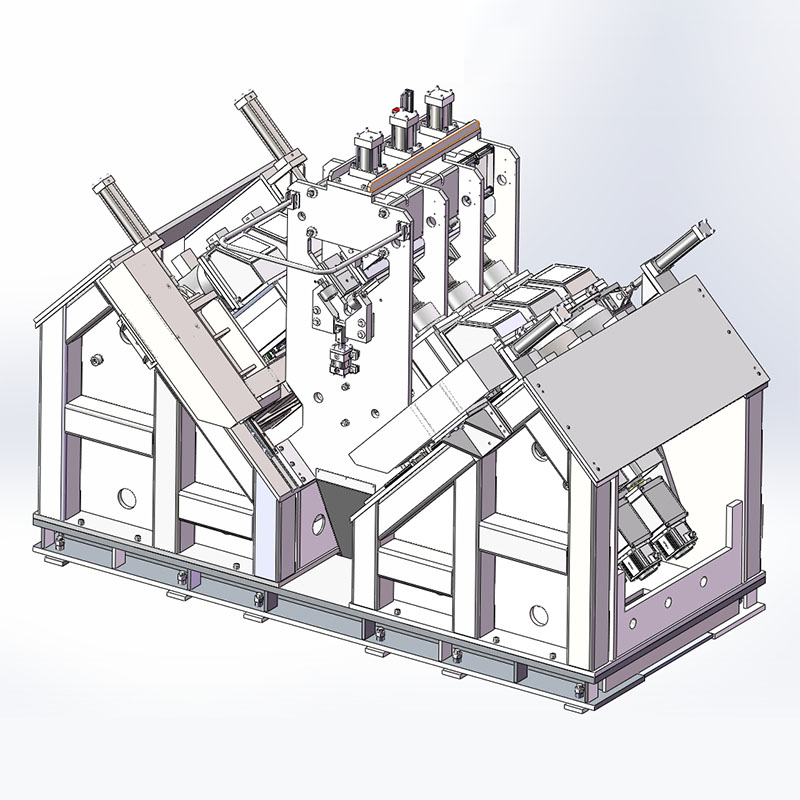

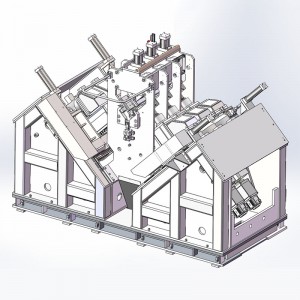

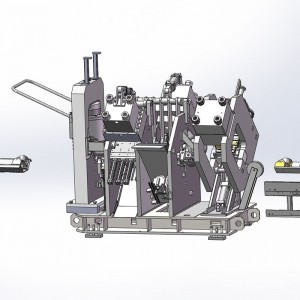

Sebopeho le tlhophiso ea morero oa mochini

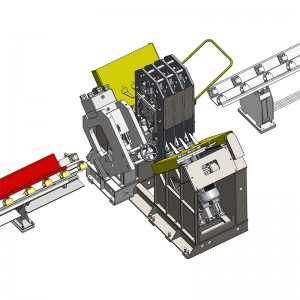

Mochini o entsoe haholo-holo ka bethe (tafole ea mosebetsi), gantry, hlooho ea ho cheka, sethala sa li-slide tsa longitudinal, sistimi ea hydraulic, Sistimi ea taolo ea motlakase, sistimi ea lubrication e bohareng, sistimi ea ho tlosa chip e pholileng, chuck ea phetoho e potlakileng jj.

Gantry e a sisinyeha ha bethe e ntse e tsitsitse. Mesebetsi e khomaretsoe ka di-clamp tsa hydraulic tse ka laolwang habonolo ka switch ya maoto, mesebetsi e menyenyane e ka kopanya dihlopha tse nne hammoho dikhutlong tsa tafole ya mosebetsi e le ho fokotsa nako ya ho lokisa tlhahiso le ho ntlafatsa bokgoni haholo.

Mochini o kenyeletsang lilepe tse peli tsa CNC, e 'ngoe le e 'ngoe ea tsona e tataisoa ke tataiso e otlolohileng e otlolohileng e nepahetseng haholo, e tsamaisoang ke enjene ea AC servo le screw ea bolo.

Morero oa mochini o amohela hlooho ea matla a ho cheka stroke ea hydraulic control automatic control, e leng theknoloji ea k'hamphani ea rona e nang le patent, ha ho hlokahale hore ho behoe liparamente pele ho ts'ebeliso.

Morero oa mochini o amohela hlooho ea matla a ho cheka stroke ea hydraulic, e leng theknoloji ea k'hamphani ea rona e nang le patente. Ha ho hlokahale hore ho behoe liparamente pele ho ts'ebeliso. Ka ts'ebetso e kopaneng ea electro-hydraulic, e ka etsa phetoho ea ho potlakisa ho sebetsa pele-pele-kapele ho khutlela morao, 'me ts'ebetso e bonolo ebile ea tšepahala.

Morero ona oa mochini o sebelisa sistimi ea ho tlotsa e bohareng ho fapana le ts'ebetso ea letsoho ho netefatsa hore likarolo tse sebetsang li tlotsitsoe hantle, ho ntlafatsa ts'ebetso ea sesebelisoa sa mochini, le ho lelefatsa bophelo ba sona ba ts'ebeletso.

Mekhoa e 'meli ea ho pholisa ka hare le ho pholisa ka ntle e netefatsa phello ea ho pholisa hlooho ea drile. Li-chip li ka lahleloa ka har'a kariki ea lithōle ka bohona.

Sistimi ea taolo e sebelisa software e kaholimo ea mananeo a khomphutha e ntlafalitsoeng ka boikemelo ke k'hamphani ea rona 'me e tsamaellana le molaoli ea ka hlophisoang, ea nang le boiketsetso bo phahameng.

■ Ha o sebedisa sistimi e sebetsang ya windows, e bonolo ebile e hlakile.

■ Ka mesebetsi ea mananeo.

■ Tsamaisa puisano pakeng tsa motho le mochini 'me u alamo ka bohona.

■ Boholo ba ho sebetsa bo ka kenngwa ka ho sebedisa keyboard kapa phihlello ya disk ya U.

Litlhaloso tse ka Sehloohong tsa Tekheniki

| Ntho | Lebitso | Boleng |

| Boholo ba sebaka sa mosebetsi | Botenya ba sebaka sa mosebetsi (mm) | Boholo ba 100mm |

| Bophara × Bolelele (mm) | 2000mm × 1600mm (Leqephe le le leng) | |

| 1600mm × 1000mm (Liece tse peli) | ||

| 1000mm × 800mm (Lisekisi tse 'ne) | ||

| Ho cheka slindle | Fetola ka potlako drill chuck | Morse 3#, 4# |

| Bophara ba hlooho ea ho cheka (mm) | Φ12mm-Φ50mm | |

| Mokhoa oa ho fetola sleed | Selei sa transducer se se nang stelle phetoho | |

| Potoloha sleed (r/min) | 120-560r/motsotso | |

| Setorouku (mm) | 180mm | |

| Ho khomarela ha haeteroliki | Ho sebetsana le ho fepa | Phetoho ea sleeve e se nang stell ea hydraulic |

| Botenya ba ho khomarela (mm) | 15-100mm | |

| Palo ea ho khomarela silindara (setulo) | Licese tse 12 | |

| Matla a ho letsa (kN) | 7.5kN | |

| Qala ho lla | Sefeto sa leoto | |

| Mokelikeli o pholileng | Mokhoa | Potoloho ea ho qobella |

| Sistimi ea haeteroliki | Khatello ea Sistimi (MPa) | 6MPa (60kgf/cm2) |

| Bophahamo ba tanka ea oli (L) | 100L | |

| Khatello ea moea | Mohloli oa moea o kopantseng (MPa) | 0.4MPa (4kgf/cm2) |

| Motlakase | Slindle (kW) | 5.5kW |

| Luml ea haeteroliki (kW) | 2.2kW | |

| Enjene ea ho tlosa chill (kW) | 0.75kW | |

| Luml e phodileng (kW) | 0.25kW | |

| Sistimi ea Servo ea X axis (kW) | 1.5kW | |

| Sistimi ea servo ea Y axis (kW) | 1.0kW | |

| Kakaretso litekanyo | L×Wx×H(mm) | Hoo e ka bang 5183×2705×2856mm |

| Boima ba 'mele (KG) | Mochini o ka sehloohong | Hoo e ka bang 4500kg |

| Sesebelisoa sa ho Tlosa Meqolo | Hoo e ka bang 800kg | |

| Selekane sa CNC | X, Y (taolo ea ho lahleheloa ke ntlha) Z (Slindle, Hydraulic feeding) | |

| Maeto | Sekhahla sa X | 2000mm |

| Sekahare sa Y | 1600mm | |

| Setulo se phahameng sa ho beha li-sleeve | 10000mm/motsotso | |

Lethathamo la lisebelisoa le likarolo tse ling

| CHE. | Khoutu | Lebitso | Bongata | Hlokomela |

| 1 | KHQ50.1 | Phetoho e potlakileng ea chuck | Sete e le 1 | E se e kentsoe holim'a slindle |

| 2 | KHQ50.1-6 | Lebala la Slindle | 2 lcs | |

| 3 | Sleeve ea ho fokotsa bophara ba 4/3 | Lekala le le leng | ||

| 4 | 4/3 Sleeve e fokotsoang e telele | Lekala le le leng | ||

| 5 | “O” lesale la 16×2.4mm | 5 lcs | ||

| 6 | “O” lesale la 11×1.9mm | 5 lcs | ||

| 7 | “O” lesale la 50×3.1mm | Lekala le le leng |

Lethathamo la Likarolo tsa Bohlokoa tse Fumaneng Mesebetsi e Meng

| CHE. | Lebitso | Letšoao | Naha |

| 1 | Terene e tataisang e otlolohileng | CSK/HIWIN | Taiwan (Chaena) |

| 2 | Luml ea haeteroliki | Feela Mark | Taiwan (Chaena) |

| 3 | Valve ea motlakase | Atos/YUKEN | Italy/Jalan |

| 4 | Enjene ea Servo | Boiketlo | Chaena |

| 5 | Mokhanni oa Servo | Boiketlo | Chaena |

| 6 | PLC | Boiketlo | Chaena |

| 7 | Mokhanni oa likhomphutha | Lenovo | Chaena |

Ela Hloko: Se kaholimo ke sebolaya-dikokwanyana sa rona se sa fetoheng. Se ka fetoloa ke dikokwanyana tsa boleng bo tshwanang tsa mofuta o mong haeba sebolaya-dikokwanyana se ka hodimo se sa kgone ho silafatsa dikokwanyana haeba ho ka ba le taba efe kapa efe e mpe.

Tikoloho ea Mosebetsi

| Matla a litšila | Lithapo tse 3 tse nang le mela e 4, 380±10%V, 50±1HZ |

| Temperature ea tikoloho | 0-40°C |

| Mongobo oa tikoloho | ≤75% |

Meaho ea rona e hlomelitsoeng hantle le taolo e ntle e ikhethang mekhahlelong eohle ea tlhahiso e re nolofalletsa ho netefatsa khotsofalo e felletseng ea bareki bakeng sa Mochini oa ho Seha oa China Angle Steel CNC o rekisoang fekthering, Re amohela bareki ba mose ho maoatle ka tieo ho buisana bakeng sa tšebelisano-'moho ea nako e telele le nts'etsopele ea bobeli. Re lumela ka tieo hore re ka etsa betere le ho feta.

Mochini oa Angle oa China CNC o rekisoang fekthering, Mochini oa CNC, Re boetse re na le likamano tse ntle tsa tšebelisano-'moho le bahlahisi ba bangata ba batle e le hore re ka fana ka likarolo tsohle tsa likoloi le tšebeletso ea kamora thekiso ka maemo a boleng bo holimo, boemo bo tlase ba theko le tšebeletso e mofuthu ho fihlela litlhoko tsa bareki ba tsoang masimong a fapaneng le libakeng tse fapaneng.

Profaele e Khutšoanyane ea Khamphani

Tlhahisoleseling ea Feme

Bokgoni ba Tlhahiso ya Selemo le Selemo

Bokhoni ba Khoebo